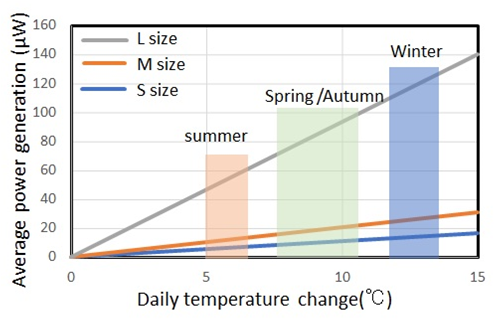

The temperature-fluctuation power generation system (TF-PGS) has a structure that combines a micro thermoelectric element and a heat storage material (Phase change material: PCM). The thermal storage material absorbs or dissipates heat from its surroundings to maintain the temperature near the phase change temperature. The heat storage material is a mixture of existing phase change materials and nanomaterials to control the desired operating temperature, heat storage volume, and heat uptake rate. The generated electrical energy is stored in a micro-storage device and used only when necessary. In principle, this element for TF-PGS does not require a heat source, enabling the sensor to be powerless and realizing an independent sensing system. Since the amount of electricity generated when the temperature change is applied is proportional to the volume of the heat storage material, a palm-top sized TF-PGS with various volumes has been developed. The output voltage of thermoelectric devices is very small, ~ mV range, thus, the voltage must be amplified in order to store it efficiently in a micro-storage device. For this reason, we developed a DC-DC converter that amplifies the low-voltage thermoelectric output with high efficiency. We also developed a power management circuit that controls the storage of energy in energy storage devices and the supply of energy from the storage devices to sensors. In addition, a supercapacitor with large capacity was developed as a micro storage device.