Best Practice and Tips to Prevent Solder Paste Dispensing Clogging issues.

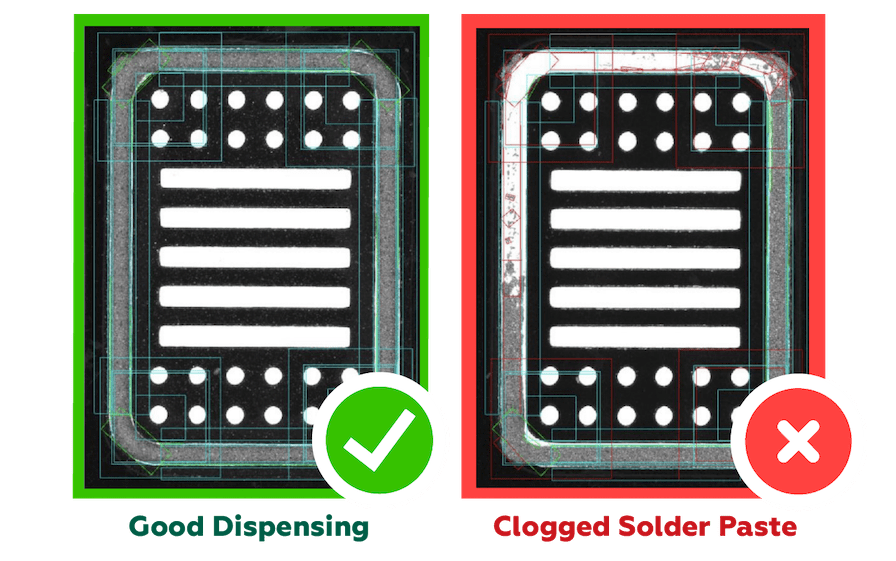

How do you prevent solder paste dispensing clog, blockage or choke? As the dispensing industry continues to grow, there has been a demand for intelligent, innovative new ideas to make dispensing easier. However, one of the major problems with solder paste dispensing is clogged or jammed dispensing valves.

Adhesive dispensing systems constantly process dispensing applications with fluids like solder paste, epoxies, and other types of adhesives. When dealing with such materials and maintaining control of repeatable, accurate, and measurable results, it is essential to upkeep your dispensing systems properly to avoid potential clog problems.

What are the top issues that dispensing equipment operators usually deal with? Here are some situations we often hear from industry players. You may be familiar with some of these issues too:

1. Loss of Yield and Unwanted Downtime Due to Clogged Needles

Under normal conditions, a dispensing valve can handle a wide range of viscosities, but if the viscosity increases past a certain threshold, the valve tends to clog. Not only is it an inconvenient hassle, but operators also need to spend time to change and clean the clogged needle. The whole operation is halted as you need to set up the machine to re-run the process again. Such downtime can hamper your efficiency and production.

2. Clog Time Can Be Tiresome and Costly

What are other losses besides production efficiency and volume of output? You would also spend unnecessarily on replacement needles to gain optimized results. You cannot rely on a clogged needle for optimum yield. Not only that, but you also waste solder paste during the removal of material and cleaning process. It disrupts work cycles to clean the needle and valves so that work can go on again.

3. Product Failure Due to Inconsistency

The last thing you would want to encounter a batch of products that are unsalable to the market. Tiny issues like clogged valves lead to big output problems causing product output to drop. It significantly lowers your UPH (Unit Per-Hour) productivity and quality output of your dispense operations, causing you to redo batches and productivity interruptions.

A clogged dispensing valve is a problem because it can cause the dispensing of a product to stop, which can be both frustrating and expensive. You certainly do not want to face such pointless downtime and potentially costly repairs.

What to Do Before Dispensing to Prevent Blockages and Clogging?

For optimum dispensing outputs, it is best to prepare and check on certain conditions before you start. Here are some situations that you might want to take note of to prevent solder paste dispensing clog.

1. Use Dispensing Grade Solder Paste.

For best performance, use dispensing grade solder paste for dispensing process. Using non-dispensing grade solder pastes (like for stencil printing and reusing unused paste from other processes) may seem like a good idea to save cost, but however its quality may be questionable and may cause more harm than good. One of the major setbacks is inconsistency. This is due to tiny micro bubbles that jams up your needle – hindering smooth quality prints.

2. Storage Climate Stability.

Store fluid materials like solder paste at the proper temperature according to the manufacturer’s guidelines. It is best practice to store your materials in a cool room of <15 °C/ 59 °F or according to the recommended manufacturer’s advice.

3. Place the Solder Paste in a Tip-down Position.

This placement avoids separation between flux and solder ball.

4. Take Note of the Expiry Date of your Materials.

Surprisingly, many operators tend to overlook this vital factor. Expired material may have dried by the time you use it, causing unwanted clogging.

5. Pair the Right Needle to Solder Paste Type.

It is essential to pair the right needle according to the specific dispensing requirements. It is recommended to use type 5 solder paste and above for general dispensing. Solder paste types depend on the dispensing size requirements.

For further info detail about clogging, please refer below links:

https://nswautomation.com/NSW/prevent-solder-paste-dispensing-clog/