What is siloxane?

In recent years, there has been a growing demand in various industries to improve the cleanliness of manufacturing processes and components. CKD offers a variety of Component Products to suit the required level of cleanliness. There are various factors that cause a reduction in cleanliness, but one of the organic pollutants is siloxane. Siloxane is one of the most common chemicals found in household products such as car waxes and cosmetics, as well as industrial products such as rubber, plastic mold release agents and defoamers. Siloxane itself is the main ingredient in silicone oil, silicone rubber, and caulking agents, which are used in a wide variety of applications. When siloxane causes components to malfunction, it can significantly reduce its life and lead to short-term breakdowns. By using components in a better environment, breakdowns can be prevented, line stoppages and costs associated with component replacements can be reduced, and as a result, industrial waste can be reduced and environmental protection can be achieved.

What are defects caused by siloxane?

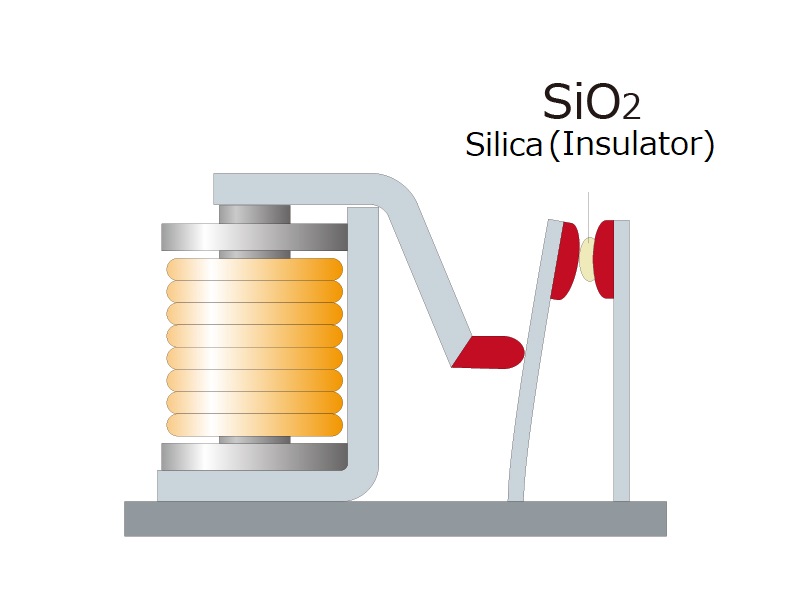

Because low-molecular siloxane has a low boiling point and easily gasifies, when siloxane adheres to a product, heat or physical energy causes a chemical change that forms silicon dioxide (SiO ), which can cause defects. Since silicon dioxide is the same composition of glass, it does not conduct electricity, and may cause poor conduction of electrical contacts, motors, sensors, etc. In addition, the siloxane generated can also cause fogging of optical lenses.

Adsorbing and Removing Siloxane

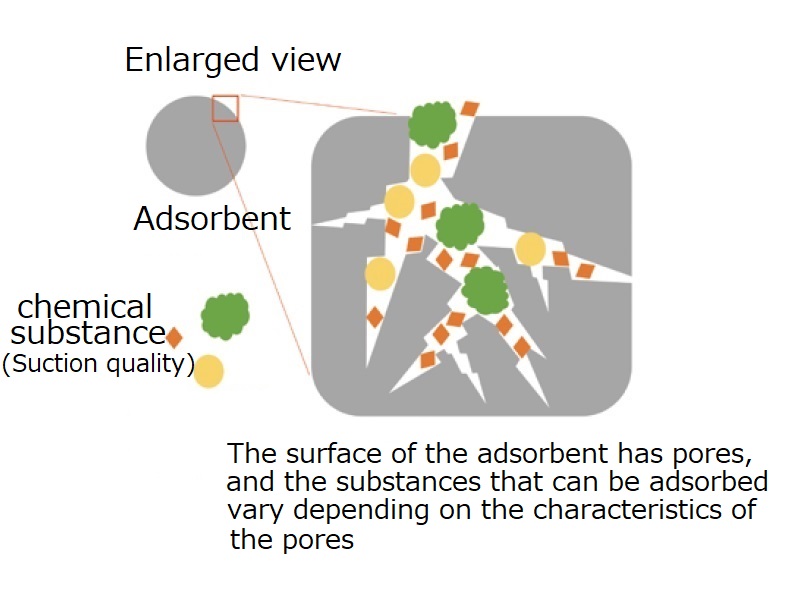

There are several methods to remove siloxane, one of which is a chemical filter using an adsorbent such as activated carbon. Chemical filters are used in air conditioning equipment such as clean rooms and in gas purification for analytical equipment. However, they are expensive and difficult to maintain because of their ability to remove siloxane with high precision. CKD's SFX Series of siloxane removers can easily remove more than 99% of siloxane by incorporating a siloxane removal filter into compressed air lines used in manufacturing processes. Chemicals and other substances are removed by adsorbing them into the pores on the surface of the activated carbon adsorbent.

Usage

If the removal rate of about 99% is acceptable, siloxane can be removed by installing the product before supplying compressed air. Customers who have already installed a filter for compressed air conditioning can connect the module without modification. If a chemical filter is already installed, the module can be installed before the chemical filter and used as a pre-filter. We believe that this will extend the life of expensive chemical filters.

Ozone is decomposed and removed

Since air contains about 20% oxygen, ozone is generated when there is ultraviolet light or electrical discharge.

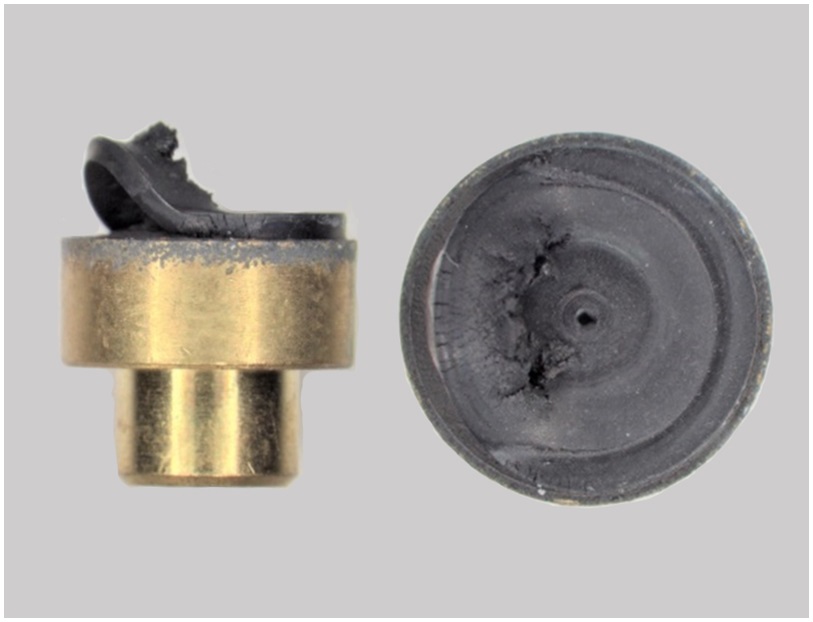

At manufacturing sites, oil-free compressors are becoming more and more widespread, causing the decomposition of ozone in the compressed air to drop and increasing the ozone concentration. Furthermore, ozone may be generated by static electricity and discharge within the air piping. Rubber used in pneumatic equipment is generally NBR because of its high oil and wear resistance. However, due to its molecular structure, NBR can crack due to ozone, resulting in deterioration of the rubber and leading to air leakage or malfunction.

In the SFX Series, carbon and ozone contained in activated carbon can be chemically decomposed into carbon dioxide and oxygen. Ozone tends to be generated in places where it is discharged near piping, so use the SFX series to decompose it and prevent deterioration of rubber.

*Siloxane adsorption and ozone decomposition cannot be done at the same time.

For Siloxane/Ozone remover SFX Series, click here.