INNOVACERA designs and manufactures technical ceramics for the analytical instrumentation industry, including components for mass spectrometers, vacuum, x-ray imaging, ion/ electron beam, spectrometers, sensors, high-pressure liquid chromatography (HPLC), medical, and telecom applications.

INNOVACERA creates specialized components that can withstand unique and challenging environments, including:

- High Heat

- Corrosive Environments

- Thermal Management Challenges

- High Mechanical Wear Environments

- Electrical Insulation Requirements

- High Temperature/High-Pressure Conditions

We provide a wide range of materials to solve problems where plastics and metals fail. Ceramics are ideally suited to provide the strength and electrical, thermal, and corrosion-resistant properties needed for analytical instrumentation. Components made from materials such as Alumina, Zirconia, and Zirconia Toughened Alumina (ZTA) solve problems where plastics and metals fail. INNOVACERA excels at matching ceramic properties to the form, fit, and function of the component. INNOVACERA is also able to supply metalized and brazed ceramic to metal assemblies for applications that require hermeticity in ultra-high vacuum (UHV).

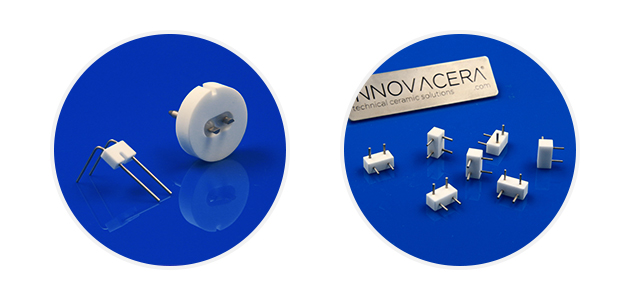

Filament Assemblies for SEM, TEM, and Mass Spectrometry

INNOVACERA is pleased to offer filament supports, a critical component in mass spectrometry applications for the analytical and medical industries. These filament supports are manufactured using Alumina ceramic, selected for its good electrical insulation and high-temperature stability. Customers can choose between two and four-pin options, with the pins brazed into the alumina insulator ready for filament welding. INNOVACERA’s welding processes include brazing and glass welding to meet the different needs of our customers.

Orifice Plates

INNOVACERA’s many years of experience in metallization and ceramic-to-metal production enable us to provide solutions according to your requirements. Our ceramic-to-metal components are ideal for use in high vacuum, High voltage, and high-pressure applications.

Quadrupole Collars, Supports, Saddles, Rods

INNOVACERA manufactures complex ceramic collars and metalized ceramic supports/saddles and rods for quadrupole mass analyzers, used in mass spectrometry instrumentation.

Supports and collar products suit a wide range of quadrupole designs utilizing the preferred rod mounting methods. Innovacera can manufacture these precision parts to accuracy tolerances and to metalize components as required for specific electrical discharge characteristics.

Quadrupole Rods, Collars and Spacers Assemblies For Mass Spectrometry

Ceramic heater for Direct insertion probe (DIP)

INNOVACERA produces high-quality ceramic heaters for use inside probes, which can be customized according to customer needs.

Ceramic heater for Direct insertion probe (DIP)

Our services include prototyping, materials design consulting, prototype production, and volume manufacturing. INNOVACERA can provide the ceramic engineering support necessary for your Research and Development projects: dedicated project teams, direct communication, and on-site technical discussions. We want to partner with you as you develop tomorrow’s technology.