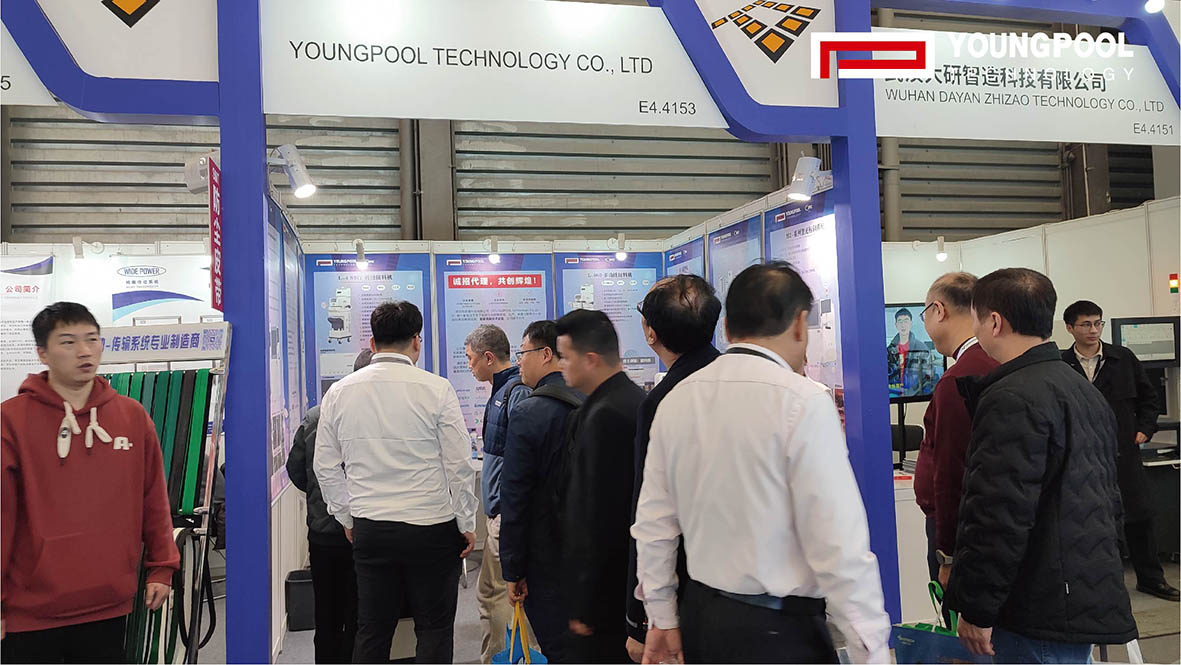

Thanks to all friends who participated in the Youngpool Technology exhibition! The Shanghai Munich Electronic Equipment Exhibition from March 20th to 22nd was a complete success with your support and attention! This is an important milestone for Youngpool Technology and a wonderful memory created together with you!

During this exhibition, we showcased the latest intelligent feeding machines, efficient production lines, and cutting-edge technological products, receiving attention and praise from many industry peers and visitors. Our team's hard work and sweat have turned into highlights at the booth, and we have felt your support and recognition, making us feel honored and gratified!

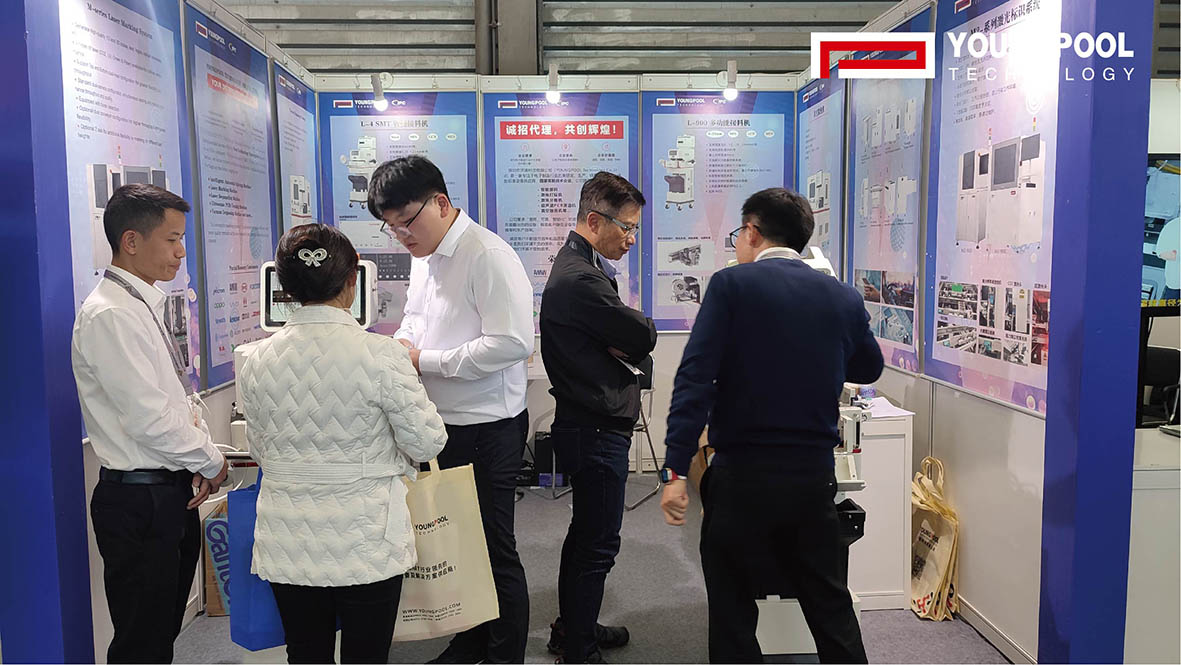

At the exhibition site, we had in-depth exchanges with visiting friends, shared technical experiences, discussed future development directions, and initiated cooperation. This face-to-face communication and exchange allowed us to better understand your needs and expectations, laying a more solid foundation for future cooperation.

Thank you to everyone for coming and paying attention, and thank you for your trust and support in Youngpool Technology! The successful completion of the exhibition is inseparable from your participation and support. We will cherish everything you have given us, stay true to our original aspirations, and forge ahead! Below are some precious moments of ours, sharing and commemorating them, leaving behind beautiful memories!

In the future, Youngpool Technology will continue to innovate and bring you more high-quality products and services, working hand in hand with you to create a better future together! Let's work together for technological innovation, industry development, and win-win cooperation!

The exhibition has come to a successful close, but our journey of cooperation has just begun. Looking forward to advancing together with you and writing a more brilliant tomorrow! Once again, thank you for your support and love! Let's share this joy and success together! Grateful to have you, and the exhibition was a complete success!

About Youngpool Technology:

Shenzhen Youngpool Technology Co., Ltd. is a standard equipment supplier dedicated to the electronics manufacturing industry, integrating research and development, production, sales, and services, and is a national high-tech enterprise.

The company has four product series including intelligent feeding, laser marking, laser cutting, and vacuum bubble removal. Adhering to the design principles of "easy to use, reliable, and intelligent," the company aims to provide the industry with the most outstanding equipment, help customers reduce equipment import and usage costs, and effectively improve yield and production efficiency.

Meeting customers' continuous efficiency and quality improvement requirements is our development purpose, and driving industry progress is Youngpool's unchanging mission. Becoming an indispensable Chinese force in the electronics manufacturing industry is Youngpool's unchanging pursuit.

Contact Information:

1. Leave a message on our WeChat official account.

2. Phone: 18124172940

3. WeChat ID: YOUNGPOOL_Tech