Nikon’s first semiconductor lithography system for packaging applications

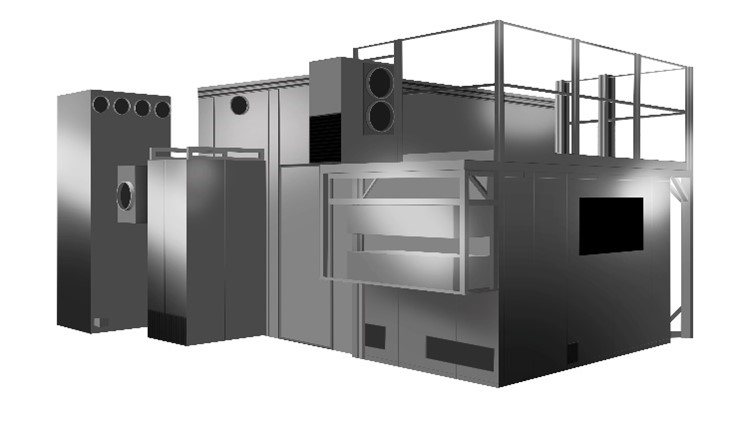

Image of Digital Lithography System

Image of Digital Lithography System

Tokyo, Japan – October 22, 2024 – Nikon Corporation (Nikon) is developing a digital lithography system with resolution of one micron (L/S) and high productivity for advanced semiconductor packaging applications. This product is scheduled to be released in Nikon’s fiscal year 2026.

The rapid adoption of artificial intelligence (AI) technology is driving demand for integrated circuits (ICs) for data centers. In the field of advanced packaging, including chiplets, the size of packages is increasing with the miniaturization of wiring patterns. This will lead to heightened demand for panel level packages that use glass and other materials suitable for larger packages, requiring exposure equipment that combines high resolution with a large exposure area. To meet these demands, Nikon is developing digital exposure equipment that combines the high-resolution technology of its semiconductor lithography systems, which has been cultivated over many decades, along with the excellent productivity made possible with the multi-lens technology*2 of its FPD lithography systems.

The digital lithography system does not use photomasks. Instead, it irradiates light from a source onto a spatial light modulator (SLM) that displays a circuit pattern and transfers it onto a substrate using a projection optical system. Since there is no need to design or produce photomasks, the digital lithography system also contributes to reducing costs, as well as shortening product development and manufacturing times.

Nikon will continue to contribute to advanced semiconductor manufacturing by providing lithography systems and solutions to fully satisfy our customers’ goals and production requirements.

*1 Abbreviation for Line and Space. Refers to the width of the wiring and the space between the adjacent wiring.

*2 Nikon’s proprietary technology that exposes multiple projection lenses in an array and precisely controls them to produce the same effect as if a single giant lens were used. This enables patterning over a wider area with a single exposure.

The information contained in this press release is current as of its date of publication.

About Nikon

Since 1980, Nikon Corporation has been revolutionizing lithography with innovative products and technologies. The company is a worldwide leader in semiconductor lithography systems for the microelectronics manufacturing industry with more than 8,000 (semiconductor) lithography systems installed worldwide. Nikon offers the most extensive selection of production-class steppers and scanners in the industry. These products serve the semiconductor, flat panel display (FPD) and thin-film magnetic head (TFH) industries. Nikon Precision Inc. provides service, training, applications and technical support, as well as sales and marketing for Nikon lithography equipment in North America. For more information about Nikon, access our website at https://www.nikonprecision.com.

####

This press release contains forward-looking statements as that term is defined in the Private Securities Reform Act of 1995, which are subject to known and unknown risks and uncertainties that could cause actual results to differ materially from those expressed or implied by such statements. Such statements are subject to risks, uncertainties and changes in condition, particularly those related to industry requirements and other risks. The Company undertakes no obligation to update the information in this press release.

For further information, please contact:

Nikon Precision Marketing Communications at:

[email protected]